Quality Assurance & Control

Home

»

Quality Assurance & Control

Coating Laboratory / Quality Control

Coating Laboratory / Quality Control Wet-Lab Process Control

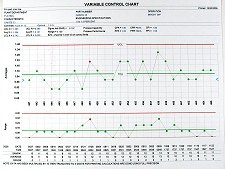

Wet-Lab Process Control Statistical Process Control Chart

Statistical Process Control Chart

Paramount Metal Finishing Quality Policy

Our goal is to provide customer satisfaction by supplying unparalleled metal finishing and zinc plating services in New Jersey, meeting customer requirements. We will succeed through developing our human resources, applying the best technologies, continually improving our quality management system and processes and by complying with the requirements set forth in ISO 9001:2000.

Process Control

Improvement Tools Actively Employed at PMF:

- ISO 9001:2015 QMS System

- Six Sigma – problem solving & process improvement

- 5Ss – facility improvement efficiency

- Kaizan events – improvement process techniques

- Process control documents (PCD) – process control

- Statistical process control (SPC) – solution control

ISO 9001:2015 Certification